As the global manufacturing industry's demand for production efficiency and flexibility increases, flexible automation systems have gradually become a key technology for various industries to improve production capacity. Choosing a suitable flexible automation system supplier can not only help companies improve production efficiency and reduce costs, but also provide stable support for the company's long-term development. However, how to make a choice among many suppliers has become a key issue. This article will discuss in detail how to choose a suitable flexible automation system supplier, analyzing from multiple perspectives such as technical capabilities, product quality, after-sales service, and cost-effectiveness, to help companies make wise decisions.

1. Understand the needs

Before choosing a supplier, you must first understand the actual needs of your company. Flexible automation are not just about automating equipment. They usually involve a variety of technologies, such as machine vision, robotics, smart sensors, data acquisition, and processing etc. Therefore, different application scenarios have different requirements for flexible automation systems.

Product type and production scale: Different product types and production scales require different types of flexible automation systems. For example, small-batch, multi-variety production lines require a more flexible system, while large-scale, standardized production lines rely more on rigid automation systems.

Production environment: Some industries, such as food and pharmaceuticals, have special requirements for the production environment, such as waterproof, dustproof or high-temperature working environment, which also requires flexible automation to have corresponding technical responses.

Technical upgrade requirements: With the continuous changes in the market, enterprises often need to upgrade and adjust production equipment. Therefore, whether the scalability and modular design of the flexible automation system can adapt to future development has become an important consideration when selecting a supplier.

After understanding your specific needs, you can know more clearly which suppliers can provide solutions that meet your requirements.

2. Supplier's technical capabilities

It is crucial to choose a high-quality flexible automation system supplier with strong technical capabilities. The supplier's technical level directly affects the reliability, stability and later adaptability of the system.

R&D strength: An excellent supplier usually has a strong R&D team that can tailor solutions according to customer needs. Suppliers should have the ability to continuously innovate and introduce new technologies that adapt to market changes.

Technical solutions: Understand whether the supplier can provide personalized flexible automation solutions based on the actual needs of the enterprise. The solution should include hardware design, software development, system integration and other aspects. Especially for complex production processes, whether the supplier can provide end-to-end technical support to ensure smooth docking during the production process.

Technical support and training: The supplier should not only provide high-quality technical support when delivering the product, but also provide post-system debugging, maintenance and personnel training services. This not only ensures the stable operation of the system, but also enables enterprise employees to master operating skills and maximize the system efficiency.

3. Product quality and reliability

Product quality is the cornerstone of whether the enterprise can operate smoothly during the production process. Flexible automation involve multiple hardware and software components, so the quality of the product directly determines the stability and production efficiency of the production line.

Supplier's quality management system: The selected supplier should have a complete quality management system, such as ISO9001 certification. These certifications can prove that the supplier's products meet international standards and undergo strict quality control processes.

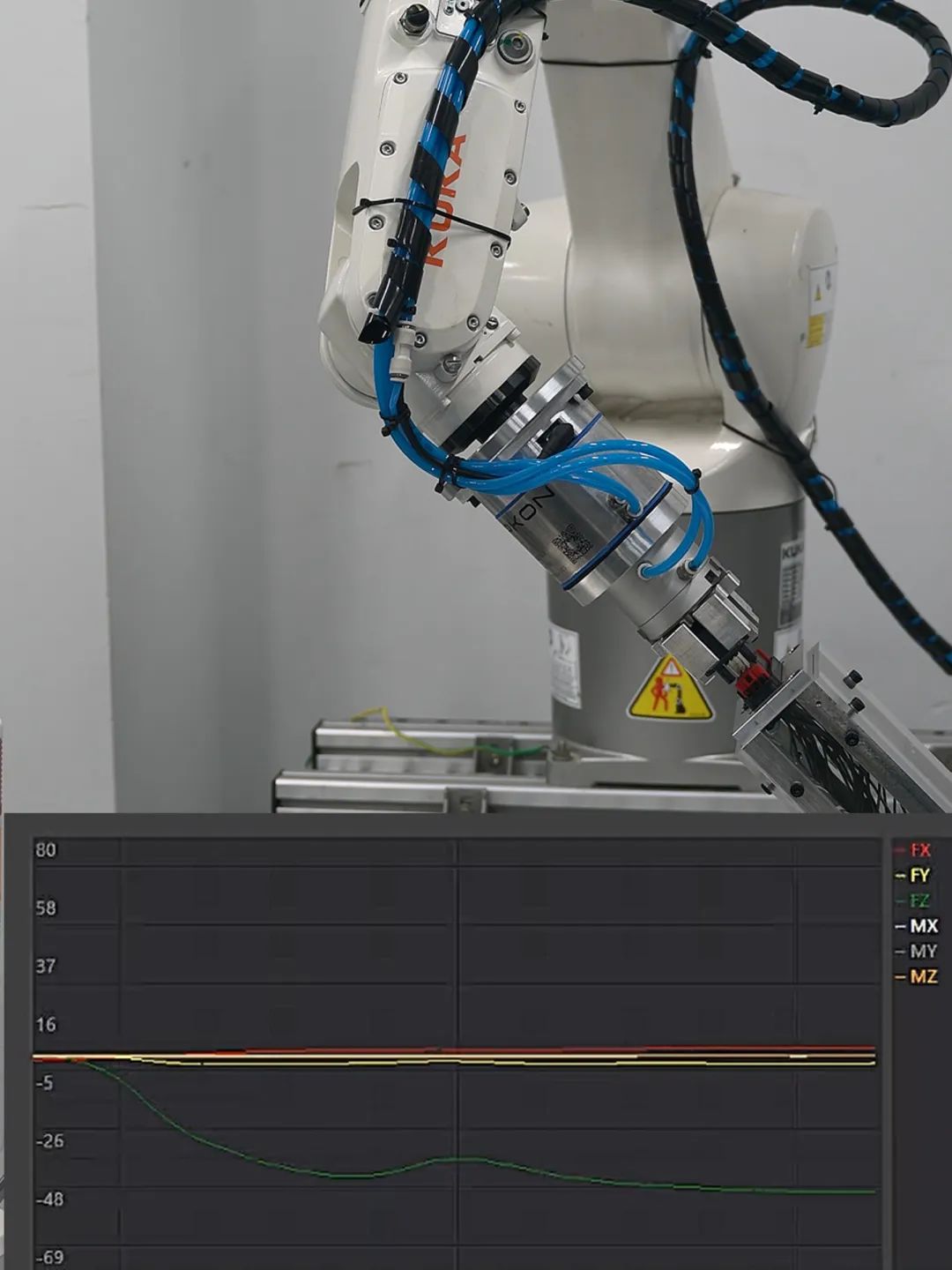

Component quality: The core components of the flexible automation system, such as robot arms, sensors, control systems, etc., should choose well-known brand components to ensure their long-term stable operation. Understanding the source and quality control standards of the components used by the supplier can provide guarantees for the company's subsequent production.

System stability and reliability: The stability of the system during long-term operation is crucial. Suppliers should provide relevant test reports or cases to prove the reliability of their systems in high-intensity production environments.

4. After-sales service and support

A high-quality supplier not only provides high-quality products, but also provides comprehensive support in after-sales service. Especially for complex technical systems such as flexible automation systems, it is difficult to maintain and troubleshoot, so timely and efficient after-sales service is essential.

24-hour technical support: Suppliers should provide round-the-clock technical support services to ensure timely response and handling when problems occur in the production line.

Regular maintenance and inspection: Regular equipment maintenance and system inspections help extend the service life of the equipment and avoid potential problems. Find out whether the supplier provides regular inspection services, as well as the corresponding warranty period and cost structure.

Quick response mechanism: In the event of a failure, can a technician be dispatched to deal with the problem in a short time? Is spare equipment provided during maintenance? These are factors that companies need to consider when choosing a supplier.

5. Cost-effectiveness and return on investment

For companies, cost-effectiveness is a factor that cannot be ignored when choosing a supplier. Flexible automation systems usually involve a large initial investment, so how to ensure its return on investment in long-term use is very critical.

Initial investment and long-term benefits: Although the initial investment of flexible automation systems may be high, it can bring returns by improving production efficiency, reducing labor costs, and improving product quality. Therefore, when choosing a supplier, in addition to paying attention to price, it is also necessary to evaluate the long-term benefits brought by the system.

Flexible payment methods: Some suppliers may provide flexible payment plans, such as installments or leasing services, which can effectively reduce the financial pressure of enterprises.

Total cost of ownership (TCO): In addition to the initial purchase cost, factors such as equipment maintenance, consumables consumption, and power consumption should also be considered. Find out whether the supplier provides cost optimization solutions to help enterprises reduce unnecessary expenses during use.

6. Supplier's industry experience and cases

The industry experience of the supplier is an important reference factor for selection. Suppliers with rich industry experience are often able to better understand industry needs and provide more suitable technical solutions.

Industry background: The supplier's successful cases in related industries can prove its technical advantages and practical experience in specific fields. If the supplier has successful cases in the same industry, this will provide an important reference for enterprises to choose suppliers.

Customer evaluation and reputation: By checking the customer evaluation and feedback of the supplier, you can understand the true quality of its products and services. Successful cases are not only a verification of the supplier's technical capabilities, but also a strong support for the company's choice.

7. Sustainable development and environmental responsibility

With the global requirements for sustainable development and environmental protection, companies should consider the supplier's environmental protection measures and responsibilities when choosing a flexible automation system supplier.

Green production: Understand whether the supplier uses environmentally friendly materials and reduces energy consumption during the production process. Whether the supplier complies with environmental certifications such as ISO14001.

Energy-saving technology: Selecting suppliers that use energy-saving technology and can effectively reduce the energy consumption of the production line will not only help reduce the company's operating costs, but also conform to the future green development trend.

Choosing a suitable flexible automation system supplier is a complex decision that requires careful consideration. In addition to product quality, technical capabilities and after-sales service, companies also need to make wise choices based on their actual needs, production environment and long-term development strategy. Through a comprehensive evaluation of suppliers, ensure that the selected suppliers can not only provide high-quality products, but also provide continuous support and assistance to the company in the later stage, so as to truly achieve production efficiency improvement and cost optimization.

www.dapkon.ai

hanghai Dapkon Technology Co., Ltd.